Introduction to FRP Tubes: Features, Manufacturing Process, and Advantages

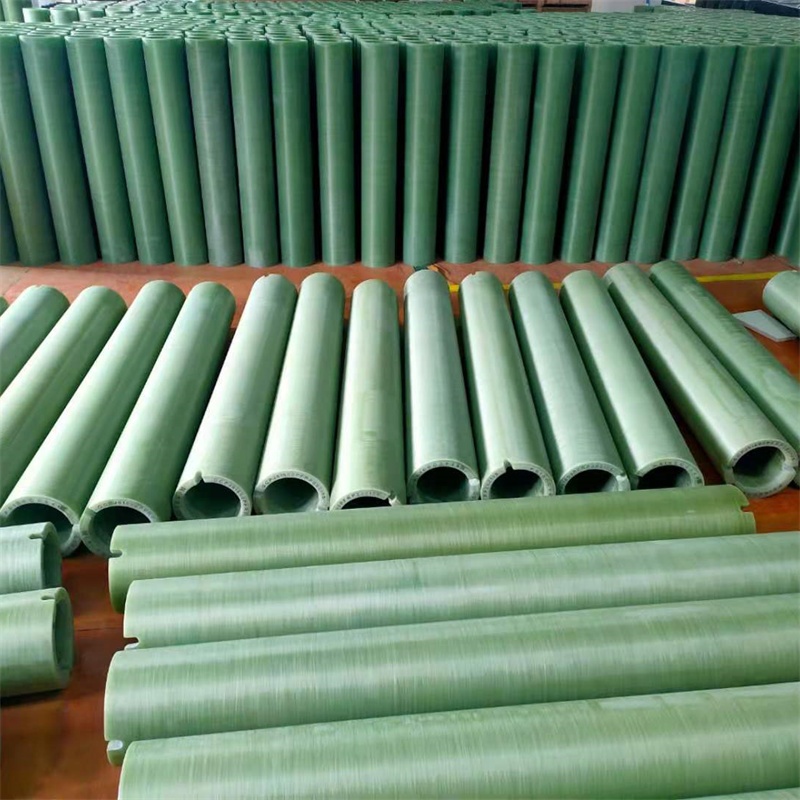

FRP tube is a composite material pipe made of reinforced polymers, such as epoxy glass fibers, carbon fibers, and aramid fibers, which share common features of high strength, durability, and corrosion resistance, widely used in various industries.

Manufacturing FRP tubes is a complex process, although mature, there are very few factories worldwide capable of producing them. Various manufacturing techniques can be used, including winding, pultrusion, and hand lay-up. Each method has its unique advantages and disadvantages, depending on the final product's application and required performance.

![]()

FRP has many advantages. It uses reinforcing fibers like glass and aramid, providing excellent strength and stiffness while being lightweight, making transportation and installation easy and cost-effective. FRP tubes have excellent corrosion resistance, with high chemical and environmental degradation resistance, making them less prone to rust and deterioration compared to metal tubes. They can withstand harsh environments, such as working in seawater or acidic or alkaline soils, and are suitable for use in the chemical processing, petroleum and natural gas processing industries.

Compared to traditional materials like steel, concrete, or PVC, FRP tubes have many advantages, such as being lighter, harder, and more corrosion-resistant and durable. They are widely used in various industries and will continue to see expanded use in the coming years.