Advantages and Applications of FRP Pipes

FRP pipes, similar to plastic pipes and metal pipes, possess superior functionality. The advantages of FRP pipes lie in their strong corrosion resistance, lightweight nature, significant cost savings, and low maintenance. FRP, a glass fiber reinforced composite material, strengthens resin. Today, we will delve into the research on what FRP pipes are, their advantages, and their application areas.

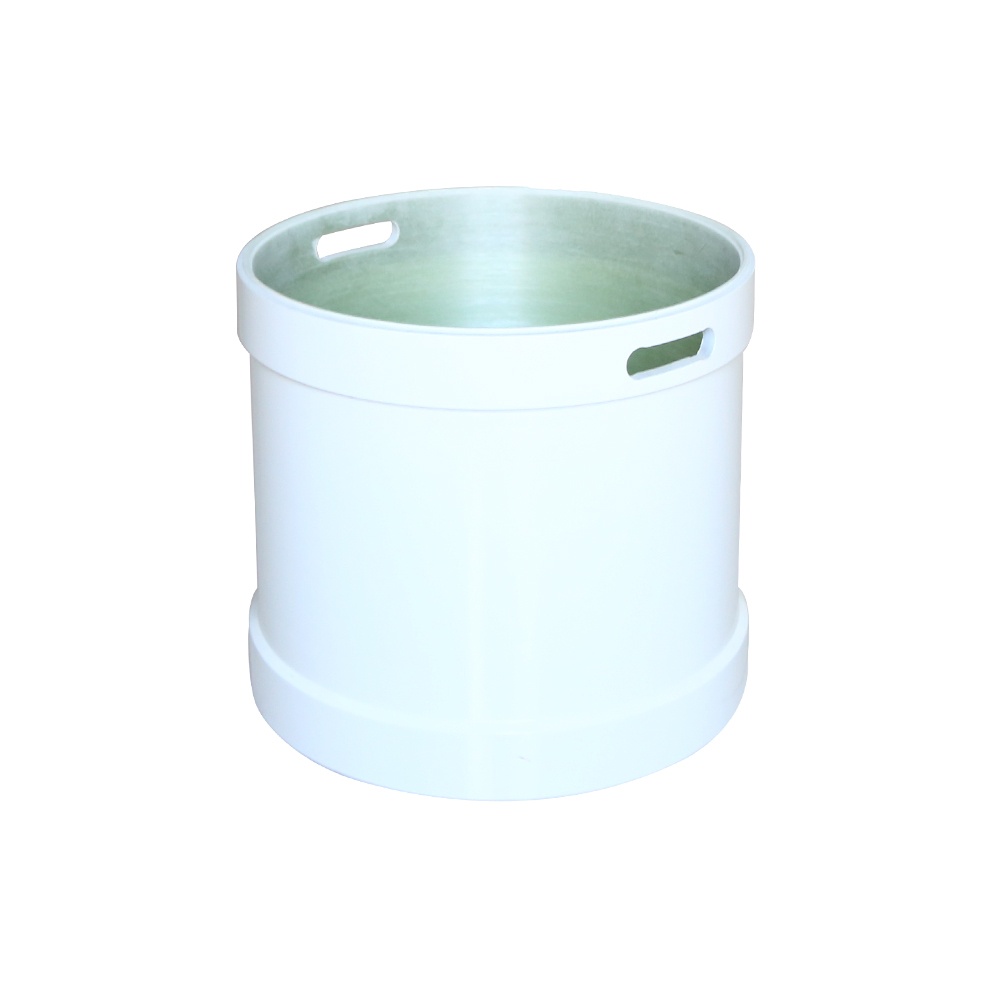

What are FRP Pipes?

FRP pipes are pipes made of fiber-reinforced plastic composed of fibers and resin. They have many excellent properties and find extensive applications in various fields.

Advantages of FRP Pipes over Steel Pipes

1. Corrosion resistance: FRP pipes exhibit outstanding corrosion resistance, withstanding the erosion of corrosive media such as acids, alkalis, and salts. They can operate stably in harsh environmental conditions over the long term.

2. Weight advantage: Compared to steel pipes, FRP pipes have a lighter weight, facilitating transportation and installation, reducing construction costs and labor requirements.

3. Cost-effectiveness: With their longer service life and low maintenance costs, FRP pipes offer high overall economic benefits. Additionally, the production and installation processes of FRP pipes are relatively simple, lowering project costs.

5. Excellent abrasion resistance: FRP pipes demonstrate remarkable resistance to abrasion, enabling them to operate steadily in highly erosive conditions for extended periods.

7. Large transmission capacity: FRP pipes have smooth inner surfaces, providing larger transmission capacities and reducing resistance losses during fluid transportation.

8. Good freeze resistance: FRP pipes exhibit good freeze resistance, allowing them to maintain normal operation even in extremely cold environments.

Application Areas of FRP Pipes

2. Water treatment industry: FRP pipes can be employed in water supply, sewage treatment, and seawater desalination fields, showcasing excellent corrosion resistance and abrasion resistance to meet long-term stable operation needs.

3. Wind energy sector: FRP pipes can be used in transmission systems within wind power generation sites, such as cable conduits and cooling system pipes inside wind turbine towers.

4. Oil and gas industry: FRP pipes find extensive applications in the extraction, transportation, and storage processes of oil and natural gas, withstanding high pressure and corrosive media requirements.

5. Marine engineering: Due to their excellent resistance to seawater corrosion, FRP pipes are widely used in marine engineering fields, including seawater desalination, offshore oil and gas pipelines, and marine platforms.

6. Mining industry: FRP pipes can be used in various processes of mining engineering, such as water treatment, tailings transportation, and chemical transportation, due to their high corrosion resistance and abrasion resistance.

7. Construction sector: FRP pipes can be applied in building water supply and drainage systems, as well as HVAC (heating, ventilation, and air conditioning) systems, possessing antibacterial properties and durability to meet the long-term operational requirements of buildings.

Key Factors to Consider When Installing FRP Pipes

When laying FRP pipes, attention should be given to design and engineering specifications, environmental adaptability, installation techniques, maintenance, and inspection. The following key factors should be considered:

1. Design and engineering specifications: Ensure that the pipe design complies with relevant engineering specifications and standards to guarantee safety and stable operation.

2. Environmental adaptability: Consider the environmental conditions in which the pipes will be placed, such as temperature, humidity, and chemical media. Select suitable FRP materials and corrosion-resistant coatings.

3. Installation techniques: Adopt appropriate installation techniques and methods to ensure correct pipe connections and fixations, avoiding issues like leakage and structural instability.

4. Maintenance and inspection: Regularly perform maintenanceand inspection of FRP pipes to detect any signs of damage, degradation, or potential issues. Implement appropriate cleaning and repair procedures when necessary.